MOOSE JAW — A Canadian fertilizer technology company has launched a multi-million-dollar project that will see the development of a potash mine near Tuxford that could produce 250,000 metric tonnes annually once fully operational.

Upcycle Minerals Inc. announced recently that it had initiated the development phase of its potassium sulphate (SOP) production plant, which will turn brine into SOP fertilizer while capturing carbon. This phase — which includes engineering work and studies — will take two years to complete, while construction of a small-scale demonstration venue will take another two years.

Once the demo plant is built, it will produce roughly 50,000 tonnes of SOP annually, while an expansion during phase 2 will push annual production to roughly 150,000 tonnes to 250,000 tonnes.

In comparison, a typical potash mine produces roughly three million tonnes annually.

Furthermore, the Tuxford plant will produce roughly 40,000 tonnes to 45,000 tonnes annually of amsul as a byproduct of the main production. Meanwhile, the SOP’s form will initially be granular, while Upcycle Minerals could have a soluble grade product by not processing the crystals.

The entire project is expected to cost more than $100 million.

The Saskatoon-based company has hired Stantec Consulting Ltd. to carry out preliminary engineering assessments and review activities in a multi-phased approach as part of the project’s development.

According to its website, Upcycle Minerals aims to become a low-cost, carbon-conscious producer in the fertilizer industry.

“We’re super excited. Since we’ve announced (the project’s launch), we’ve had a lot of positive feedback (and) a lot of interested parties,” said Jonathon Phinney, president and director. “It’s been great so far.”

Phinney explained that the company has been planning this project for several years, but all the necessary aspects came together recently to allow it to announce the initiative’s kickoff.

Continuing, he said the company owns several locations that will feed the project, but the main processing plant will be somewhere near Tuxford. Upcycle Minerals will source feedstock from the Tuxford potash mineral permit and two alkali lakes — Whiteshore and Lydden — near Biggar. It will also acquire gypsum from a quarry in Manitoba.

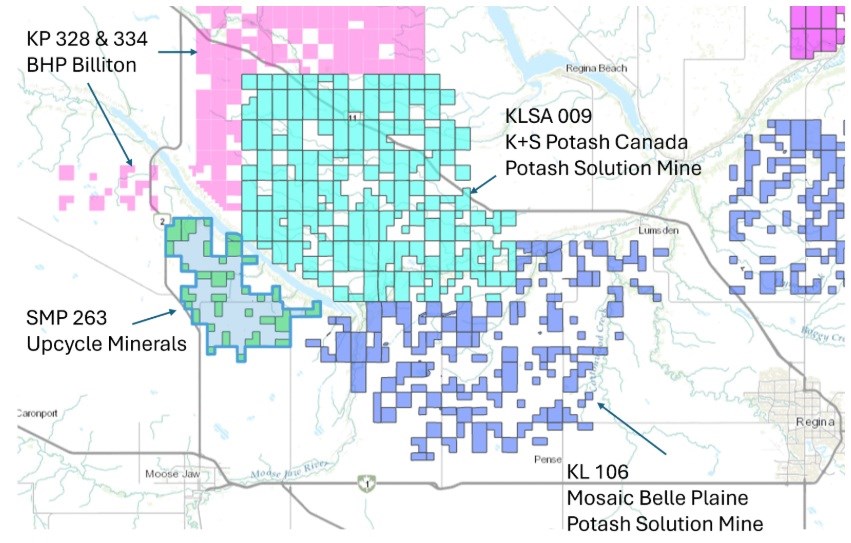

The mineral permit borders K+S Potash’s Bethune and Mosaic’s Belle Plaine solution mining properties. There is also a nearby natural gas pipeline, while an ammonia production plant is roughly 30 kilometres away.

The permit consists of 4,226 hectares (10,565 acres) of Crown land and has a total area of 10,717.2 hectares (26,793 acres) including free-held mineral rights. The permit is roughly 18 kilometres north of Moose Jaw and borders Tuxford on the western edge and Buffalo Pound Lake on its north/east boundary.

The company president noted that SOP is a premium type of fertilizer since it is comprised of potassium and sulphur macronutrients.

“The North American market is very underserved. (SOP) enjoys a significant price premium over regular potash,” Phinney said. “There’s a much smaller market than conventional potash, but we feel there’s room for us.”

While the company plans to focus on the North American fertilizer market with the SOP and amsul that the Tuxford plant produces, it plans to target the United States once SOP output starts to increase after phase 2 is completed.

Besides producing SOP, the plant will also produce — as a byproduct — ammonium sulphate fertilizer and precipitated calcium carbonate, added Phinney. Any carbon dioxide that the venue produces will be pumped into the precipitated calcium carbonate product.

Visit upcycleminerals.com for more information.